Industrial Continuous Waste Plastic Pyrolysis Plant

converting waste plastic into fuel

Main Features of Niutech Pyrolysis Plant

Introduction of our product

Continuous Operation

Hours continuous running. Whole pyrolysis machine can achieve continuous feeding, continuous discharging.

Multiple Certifications

Whole equipment has obtained CE, TUV, ATEX certifications. Waste pyrolysis emission completely comply with EEA & EPA standards.

Great Financial Benefits

After pyrolysis, waste polymer turns into high-added value product without second pollution to nature environment.

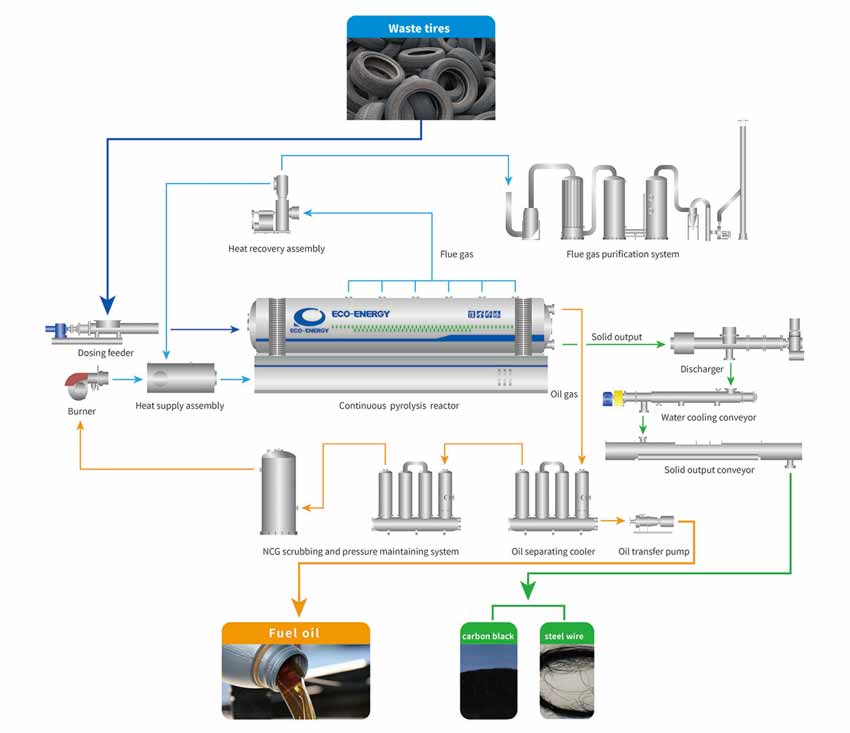

Technical process

Model as scrap tire pyrolysis line.

Pyrolysis Process

View the pyrolysis flow

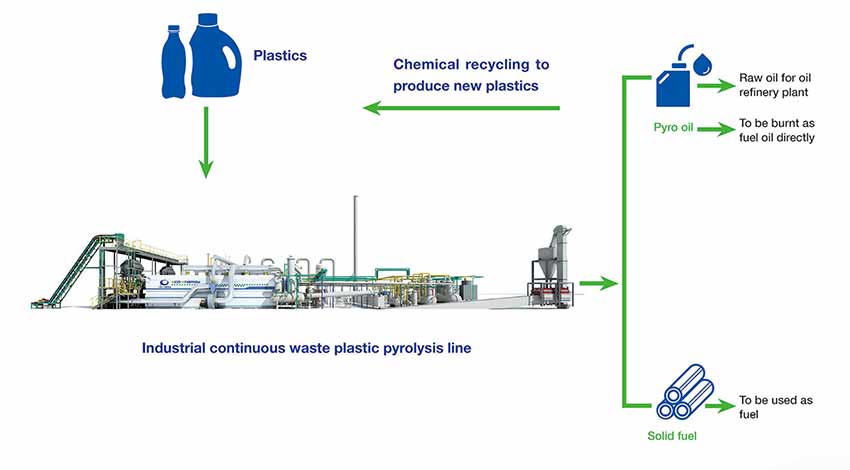

Waste plastics will convert to high-added value products such as pyro oil and solid fuel through pyrolysis, and the pyro oil is able to produce new plastics as raw material by chemical recycling.

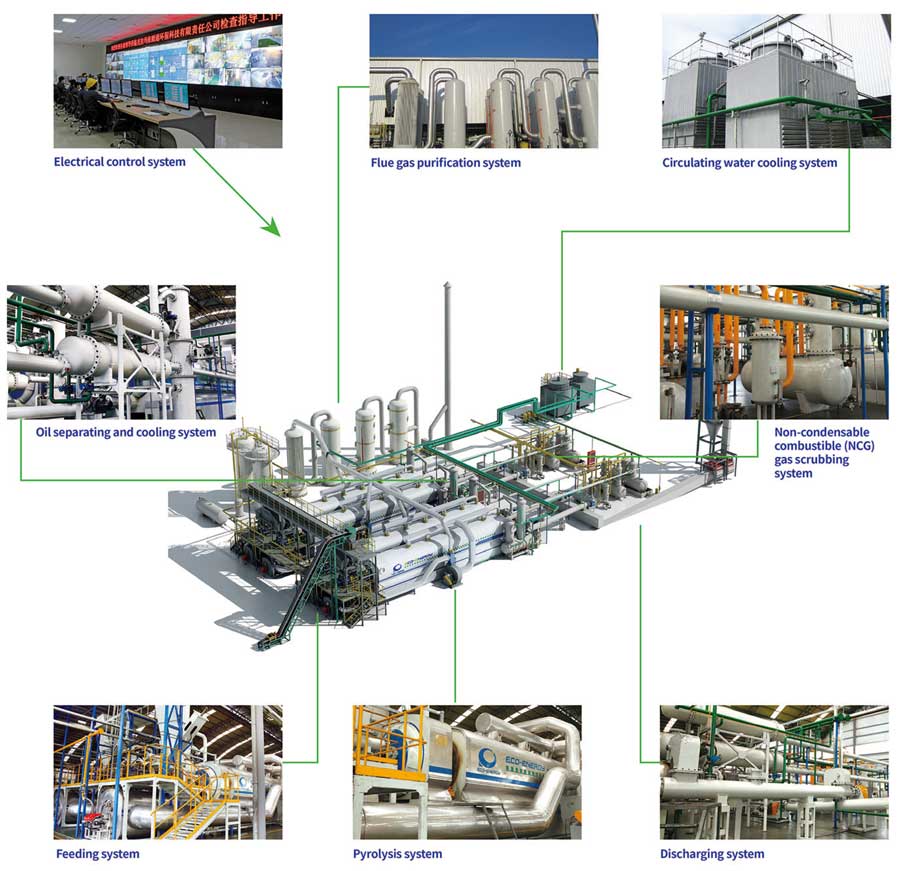

Sub System

8 components to ensure the operation of waste plastic pyrolysis machine.

- Feeding ——The raw material is automatically transported to the transitional hopper through the feeding conveyor. This system can also realize on-line weighing, conveying, feeding seal and other functions.

- Pyrolysis——In the oxygen-free or oxygen-poor environment, the pyrolysis system function is to complete the pyrolysis reaction of organic waste or hazardous waste and convert the raw material into pyro oil, NCG and solid output under normal pressure, low pyrolysis temperature or catalyst action.

- NCG scrubbing——While to remove the acid components in NCG, such as hydrogen sulfide, the pressure is also maintained within a reasonable range through the NCG scrubbing system and further supply energy to downstream.

- Circulating water cooling——The main function of this system is to cool the outputs from pyrolysis system and flue gas with water as cooling medium. The cooling water is circulated in the way of in-direct heat exchange, which does not contact any material directly, and there’s no waste water generated.

- Oil separating and cooling——This system is to cool the gas phase output from pyrolysis reactor to the safe temperature and separate them according to the different boiling points.

- Discharging——The main function of discharging system is to complete the discharge seal, cool and convey the solid output.

- Flue gas purification——The main function of this system is to cool down and purify the flue gas. Through multi-stage purification and comprehensive treatment, the harmful substances in the flue gas can be removed, and the flue gas discharged into the atmosphere can meet the emission standards in various countries and regions.

- Electrical control——Electrical control system adapts PLC/DCS control system to automatically control the control points. It also has the functions of date collection, calculation, record, printing record, safety alarming etc.

Projects & Cases of Niutech

Our actual pyrolysis project cases