Pyrolysis technology is an effective measure to the reductive, harmless and recycling treatment of waste polymers.

Heating temperature, heat transfer surface,heat transfer efficiency, operating pressure, retention time and anti-polymerization techniques are the six key factors of pyrolysis process and equipment.

- Heating temperature

Heating temperature is the most important control parameter in the pyrolysis process, which affects the pyrolysis speed rate, output composition and yield of raw material as well as service life of equipment.

If heating temperature is too high, it will increase the fuel consumption and reduce the oil yield and equipment service life; If heating temperature is too low, it will reduce the pyrolysis rate of raw material, and there will be incomplete pyrolysis that is the pyrolysis rate or oil content of solid output can not meet the requirements of relevant national standards.

- Heat transfer surface

Heat transfer surface is the key factor that affects the capacity and heat efficiency of pyrolysis equipment.

If heat transfer surface is insufficient, it will reduce the capacity; Although heat transfer surface can be increased by increasing the equipment volume, but it will increase the secondary pyrolysis probability of gas phase output and surface heat loss, which reduces the heat utilization efficiency and increases the fixed investment and operating costs for the equipment.

- Heat transfer efficiency

Heat transfer efficiency is the key factor that affects the economic benefit of pyrolysis equipment.

When heat transfer efficiency is high, it will reduce the fuel consumption, carbon emission and operating costs; When heat transfer efficiency is low, it will reduce the process capacity or pyrolysis rate of raw material, which increases the operating costs.

- Operating pressure

Operating pressure is the key factor that affects the safety and environmental protection of pyrolysis equipment.

If positive pressure is too high, it is possible to occur the leakage of pyrolysis gas phase outputs. There are security risks, causing environmental pollution; If negative pressure is too low, it is possible that the air enters into the pyrolysis reactor. There are greater security risks.

- Retention time

Retention time is the key factor that affects the pyrolysis rate and the composition of pyrolysis outputs.

If retention time is not enough, it will lead to the incomplete pyrolysis of raw material, which makes the pyrolysis rate lower than the standard valve; If retention time is too long, it will increase the probability for secondary pyrolysis of oil gas and reduce the oil yield, which reduces the operating efficiency of whole production line and increases the operating costs.

- Anti-polymerization techniques

Anti-polymerization techniques is the key factor that ensures the long-term continuous and stable operation of pyrolysis equipment.

Adopting the anti-polymerization techniques to reduce the polymerization of unsaturated compositions such as olefin which can improve the oil quality and extend the operating time of equipment.

Industry difficulties

Pyrolysis technology is an effective means for the harmless, resource-recycling, and reduction treatment of polymer waste. But due to there are some industry difficulties such as easy-coking of pyrolysis system, difficult dynamic sealing of feeding and discharging, and easy-polymerization of outputs, it is difficult to realize the industrial continuous operation of pyrolysis equipment under the premise of safety and environmental protection.

Solve the industry difficulties

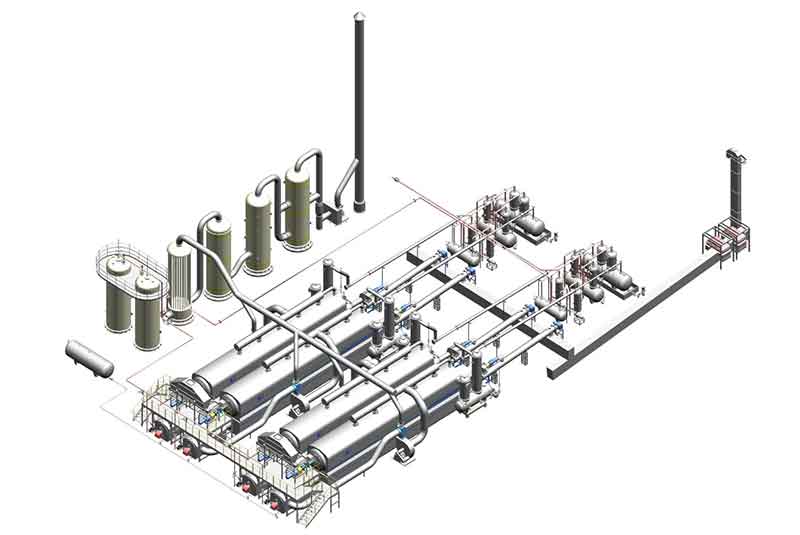

The standard single set of pyrolysis equipment designed and manufactured by Niutech Environment Technology Corporation contains nearly ten thousand technical parameters. Through the trial and error and systematic design for a series of key factors of pyrolysis technology such as heating temperature, heat transfer surface, heat transfer efficiency, operating pressure, retention time and anti-polymerization techniques, Niutech have solved the industry difficulties above and realized the industry continuous operation of pyrolysis equipment under the premise of safety and environmental protection.

- Solve the coking with thermal distribution technology

Easy-coking of pyrolysis is a worldwide problem in pyrolysis industry

There are some general problems of the raw material of pyrolysis such as poor heat transfer performance and raw material heated unevenly. The material is easy to form coking and carbon deposition on the heat transfer surface of the equipment, which reduces the heat transfer efficiency and forms blockage, and it needs to further raise the heating temperature. This will cause a series of problems such as reduced service life of equipment and incomplete pyrolysis of materials, which results in the pyrolysis being not operating normally. If not handled properly, it will even lead to major safety risks.

Therefore, Anti-coking has become the primary technical difficulty needs to be solved in the pyrolysis field, which is also one of the main reasons that it is extremely difficult to achieve industrial continuity in the pyrolysis industry.

Through a series of patent technologies and special designs, Niutech technology improve the raw material heating condition and movement pattern. The unique thermal distribution technology eliminated the existing condition of coking from the basic, while completing the material dynamic evenly heated and fast reaction, so that the production line achieved anti-coking continuous stable operation.

Niutech’s thermal distribution technology has awarded 11 authorized patents.

- Solve the dynamic sealing in pyrolysis process with hot air tight technology

Dynamic seal is one of the key technologies that realizes the industrial continuous pyrolysis. That means, it ensures the continuous feeding and discharging of pyrolysis reactor, and prevents the air from entering into the reactor and oil gas leakage in the reactor, in order to realize the safe, stable and continuous pyrolysis processing for raw material in the oxygen-free or oxygen-poor conditions.

Due to many reasons such as different compositions of raw material, high or low water content, etc., the pressure changes at any time, which increases the difficulty of dynamic seal.

Niutech innovatively invented the unique seal techniques that combines with “process + structure + material”, and controlled operating pressure within the set value range stably all the time achieves the production line stable dynamic seal under continuous feeding and discharging.

- Niutech’s hot air tight technology has awarded 11 authorized patents.

Solve the easy-polymerization of pyrolysis gas phase output with anti-Polymerization technology

Small molecular organics (mainly olefin) produced by pyrolysis are easy to polymerize and generate macromolecular chain matters such as colloid and asphaltene, etc., which can easily cause blockage of equipment and pipelines and affect the long-term stable operation of production lines.

The anti-polymerization techniques and technology independently researched and developed by Niutech, which applied the gas-liquid mixed flow process to quickly reduce the temperature of gas phase output to the design temperature according to the different boiling point of the gas phase output. And it achieved the rapid separation of gas and liquid, mitigated polymerization possibility, improved oil yield and ensured the long-term stable operation of production line.

Niutech’s anti-polymerization technology has been awarded 3 authorized patents.

At present, Niutech environment technology corporation has become minority enterprises in China with the actual delivery capacity for waste polymers industrial continuous pyrolysis equipment.

No comment