The technology of converting waste plastic into oil began in the 1980s, but there was no large-scale industrialization of the emergence. Most of the projects at that time were in the form of small production workshops, with backward process and rudimentary equipment, lacking high-value recycling technology and supporting high-value utilization of products. The secondary pollution produced during the production process would have a more serious impact on the environment if not disposed of properly, so the technology transferring waste plastic to oil at that time caused controversy in the environmental protection community.

After entering the 21st century, the dependence on plastics in human production and life has become more and more severe, and the resulting environmental problems have intensified. When plastic pollution in the global oceans and soil is becoming worse, and even when our resources are facing depletion, the plastic chemical recycling is being explored again. With the development of waste plastic pyrolysis technology, the process of converting waste plastics into oil has been greatly enhanced. The pyrolysis technology is more in line with the human concept of harmless, reduction and resourcefulness of resources. The recycling of waste plastics is developed from a single physical recycling to the direction of diversified environmental disposal, waste plastic pyrolysis project is becoming the next challenge of environmental protection industry.

After entering the 21st century, the dependence on plastics in human production and life has become more and more severe, and the resulting environmental problems have intensified. When plastic pollution in the global oceans and soil is becoming worse, and even when our resources are facing depletion, the plastic chemical recycling is being explored again. With the development of waste plastic pyrolysis technology, the process of converting waste plastics into oil has been greatly enhanced. The pyrolysis technology is more in line with the human concept of harmless, reduction and resourcefulness of resources. The recycling of waste plastics is developed from a single physical recycling to the direction of diversified environmental disposal, waste plastic pyrolysis project is becoming the next challenge of environmental protection industry.

Waste plastic pyrolysis technology can reach 100% utilization of waste plastic. It not only can treat solid waste residue harmlessly, but also have no secondary pollution, and will not produce dioxins. This not only can avoid polluting the environment but also recycle resources.

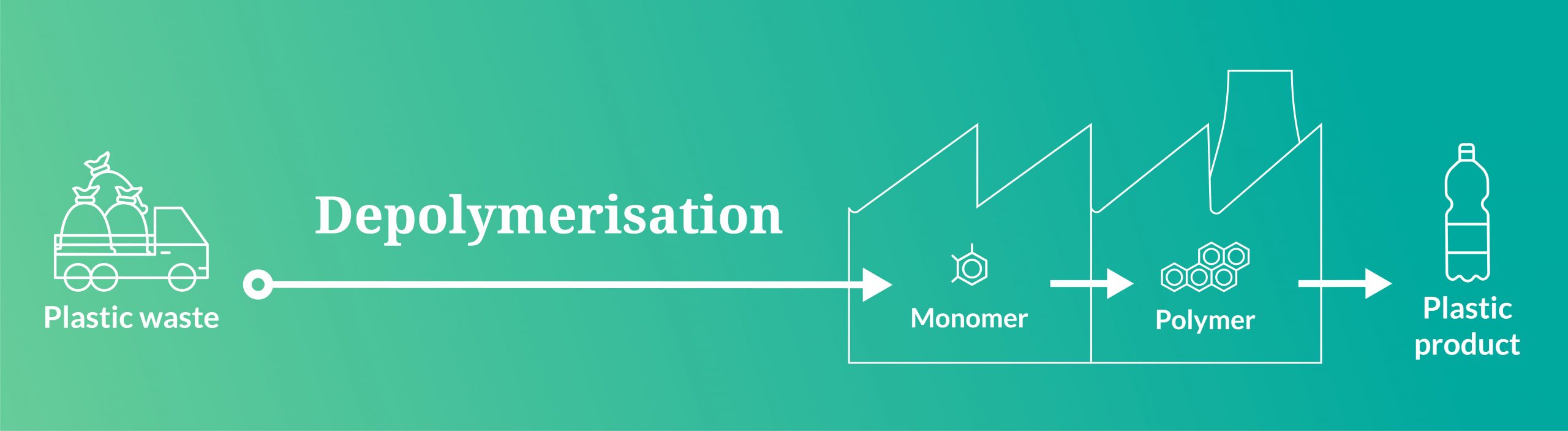

This technology converts low residual value waste plastics into plastic oil through waste plastic pyrolysis technology, which is then used as a raw material for the production of new plastics. At present, the waste plastic recycling machines and equipment equipped with advanced pyrolysis technology have fully realized commercial operation and large-scale industrial application, realizing the “ petroleum – new plastic – waste plastic- plastic oil – new plastic” closed-loop industry chain of plastic recycling economy.

For a long time, the recycling of waste plastics could only rely on a single method of physical recovery and recycling, but the emergence of this technology has achieved the closed-loop industrial chain of plastics recycling economy. It is suitable for the environmental disposal of mixed waste plastics, plastic waste and other low-value waste plastics. The industrial continuous waste plastic pyrolysis technology and equipment developed by Niutech is the cutting-edge technology in the current waste plastic optimization technology and equipment series.

At present, the world is constantly improving the top-level design of waste plastics reuse and promoting the establishment of waste separation and recycling governance system. Most importantly, with the encouragement of policies and technology from various countries, the waste plastics pyrolysis industry has presented a large and promising market that has attracted many advanced enterprises. At present, Sinopec, CNPC, BASF, ExxonMobil, DOW, SK geocentric and other domestic and foreign petrochemical giants have been building and using plants for pyrolysis equipment.

Email: contact@niutech.com

Tel: 86 531 86196301

No comment