Plastic pollution

As society develops, human reliance on plastic grows by the day. Because plastic is light, flexible, relatively inexpensive and durable, it can be used in everything from grocery bags to even the nozzles of rockets.

Although the problem with plastic stems from its difficulty in natural degradability. In addition to its widespread versatility, waste plastic is causing serious environmental damage at an alarming rate, and plastic pollution is also known as “white pollution.

Plastic may be one of the most versatile materials on the planet. For example, all the plastic made in the last few decades would be enough to wrap the entire planet if it were cling film.

Plastic is also one of the worst pollutants causing unprecedented damage to the world’s fragile ecosystems. The oceans and all lives within them are probably suffering the most.

Even conservative studies estimate that more than 8 million tons of plastic are dumped into the ocean each year. And once entering into the natural environment, it can take hundreds or even thousands of years to fully decompose.

Even though the plastic will decay into smaller pieces, it will further break down into smaller and smaller pieces, and then into so-called microplastics——pieces of plastic no longer than 5 mm.

Microplastics can easily pass through water filtration system and finally enter into the oceans and lakes which pose a potential threat to aquatic life.

How to solve “white pollution”

In the face of this situation, there are ways not only to solve the problem, but also to completely reverse the harm caused by plastic in the world.

Currently, some viable alternatives can completely replace plastic, while there are also other recycling solutions to reduce the plastic already existing. In addition, there is a more complete system and scientific and reasonable method to eliminate waste plastic from the environment——recycling of waste plastic.

Current waste plastic recycling methods are mainly physical recycling and chemical recycling. Physical recycling to landfill, melt granulation, modification, in-situ utilization, etc., has gained many applications. However, there are disadvantages such as restrictions on treatment types of components, more restrictions on recycling, not easy to degrade, land pollution, ecological pollution, etc. Thus, physical recycling has been increasingly restricted by the countries.

Chemical recycling, which is the decomposition of polymeric materials in waste plastics by pyrolysis, eradicating oil gas, etc. Advanced recycling is the key to ending plastic waste and preventing plastics from entering the environment, which can capture and reuse the vast amount of waste plastic that is not currently being recycled.

Cutting-edge technology to solve white pollution

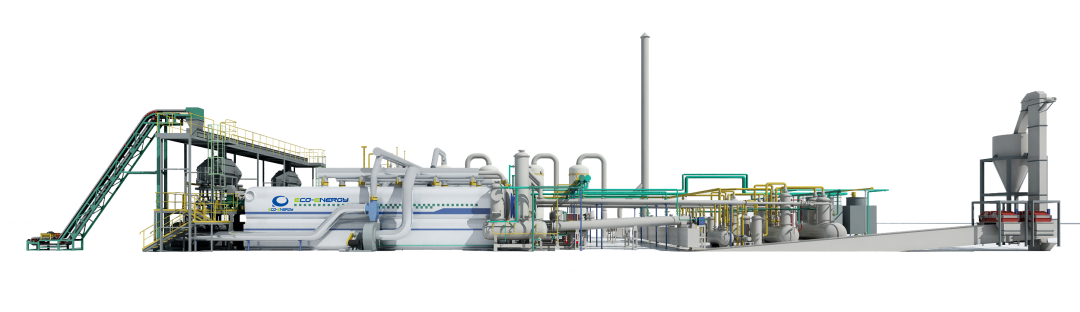

The top waste plastic processing technology from China – Niutech waste plastic pyrolysis equipment, which can maximize the recovery and recycling of waste plastic under the premise of safe, environmentally friendly, continuous and stable operation, with a raw material pyrolysis rate of >99%. Niutech waste plastic pyrolysis equipment can produce high-value output such as fuel oil, solid fuel and NCG, and realize the resource utilization of waste plastic. Fuel oil can be processed into naphtha, and then made into new plastic products, which realizes the cycle from waste plastic to new plastic.

After more than 30 years of concentration and accumulation, Niutech has developed an industrial continuous waste plastic pyrolysis production line to realize the great innovation of “turning plastic waste into wealth” by transforming plastic waste into valuable chemicals.

Niutech organic waste pyrolysis technology and equipment have been successfully used in many countries in Asia, America and Europe. For example, in a domestic waste recycling base in Thailand, plastic from domestic waste is pyrolyzed by Niutech pyrolysis equipment to obtain high quality fuel fraction and NCG, which can be further processed to obtain diesel or refinery raw material oil for use.

A waste plastic treatment project in Denmark, in cooperation with global chemical giant BASF, which uses Niutech waste plastic pyrolysis technology and equipment, and the pyrolysis output are then used to make new plastic, thus saving a large amount of petroleum raw materials.

A domestic waste treatment center in the America also uses Niutech waste plastic pyrolysis technology and equipment to collect local plastic waste and output fuel oil as a chemical raw material after treatment, which not only solves the local “white pollution” problem, but also achieves a high economic utility.

“White pollution” is ravaging the world, and solving the problem of plastic pollution has become a global consensus. Niuteh uses the power of science to solve the problem of white pollution, and after the industrial application of practical projects in many countries around the world. Niutech has been a technology worth promoting and spreading to solve “white pollution”.

No comment