The composition of oily sludge in oil fields is extremely complex. It is an extremely stable suspension emulsion system, containing a large amount of aged crude oil, wax, asphaltenes, colloids, suspended solids, bacteria, salts, acid gases, corrosion products, etc. In addition, it also includes a large amount of water treatment agents such as coagulants, corrosion inhibitors, scale inhibitors, and fungicides added during the production process. And because of its large size, it not only takes up a lot of cultivated land after discharge, but also pollutes the surrounding soil, water and air.

Countries around the world have started research on the treatment of oily sludge since the early 1970s. Due to the extensive geographical distribution of oil fields and the complexity of oily sludge components, oil sludge treatment technology is difficult and costly. Therefore, its processing technology is also diverse.

At present, some petrochemical enterprises in the United States, France, Germany and China process oily sludge through rotary furnaces or fluidized bed incinerators. The incineration residue is used for road construction or buried in a designated landfill, and the heat generated by incineration can be used for heating, power generation, etc. Experimental research was carried out on oil sludge from an oil refinery in southern India, and an incineration treatment system with a processing capacity of 2 t/h was designed. The combustion efficiency and incineration efficiency reached 98% or even 99%, respectively, and the residue can be non-toxic landfill.

At present, the global treatment methods for oily sludge generally include: incineration, biological treatment, thermal washing, solvent extraction, chemical demulsification, solid-liquid separation, coking, oily sludge profile control, and comprehensive utilization of oily sludge wait.

However, many methods have some problems and are unsuitable for practical applications. For example, the incineration method is energy-consuming, easy to produce secondary pollution, and difficult to recycle oil resources; the biological treatment method takes 41 days to biodegrade 97% of petroleum hydrocarbons; the solvent extraction method has the problems of long and complex process, high treatment cost, and is only applicable to oily sludge containing a large amount of hard-to-degrade organic matter; the chemical emulsion breaking method requires additional emulsifier and heating. The chemical emulsion breaking method requires additional emulsion breaker and heating for heavily emulsified oil-bearing sludge; the solid-liquid separation method has low oil recovery rate for oil-bearing sludge with high oil content and serious pollution.

Therefore, none of these methods has been applied effectively. With the increase of pollution and the development of corresponding technology, many companies have developed a variety of new processes for treating oily sludge, after studying the composition, structure and characteristics of oily sludge.

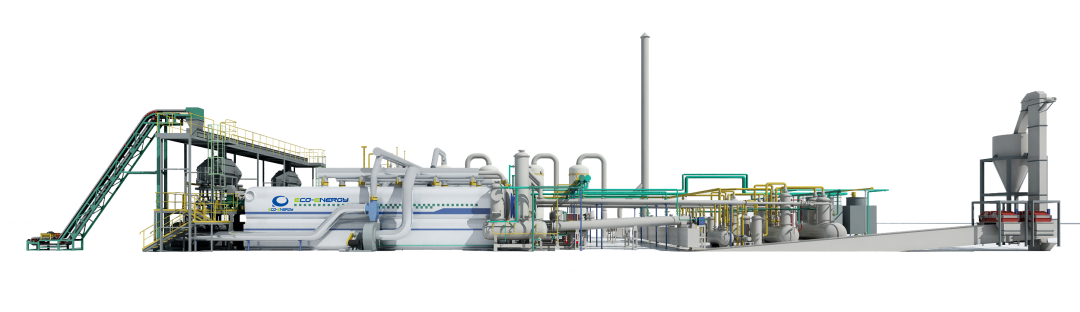

With the rapid development of pyrolysis technology, the application of pyrolysis for oil sludge disposal is getting more and more attention from large oil companies and oil service companies. The industrial continuous oil sludge pyrolysis technology and equipment developed by Niutech has broken through various difficulties and achieved effective reduction of disposal cost and stability and efficiency, and this technology has been adopted by many oil giants, which has obvious advantages compared with other treatment methods.

Email: contact@niutech.com

Email: contact@niutech.com

Tel: 86 531 76196301

No comment