With the development of automobile industry, the output of its accessory waste tires is also increasing year by year. For example, ordinary household cars need to replace tires every five years or so, which has become one of the most common solid wastes in life.

About Scrap Tire Pyrolysis Process

Because of the heat resistance, aging resistance, water resistance, biodegradation resistance and mechanical damage resistance of rubber, it is difficult to degrade naturally. If not dealt with in a timely manner, it will occupy land, affect the environment, and easy to breed mosquitoes, fire, and so on, endangering the environment we live in.

The disposal of scrap tire is also an important environment class. As the ultimate processing method, pyrolysis technology is the most thorough and resourceful means of waste tire treatment.

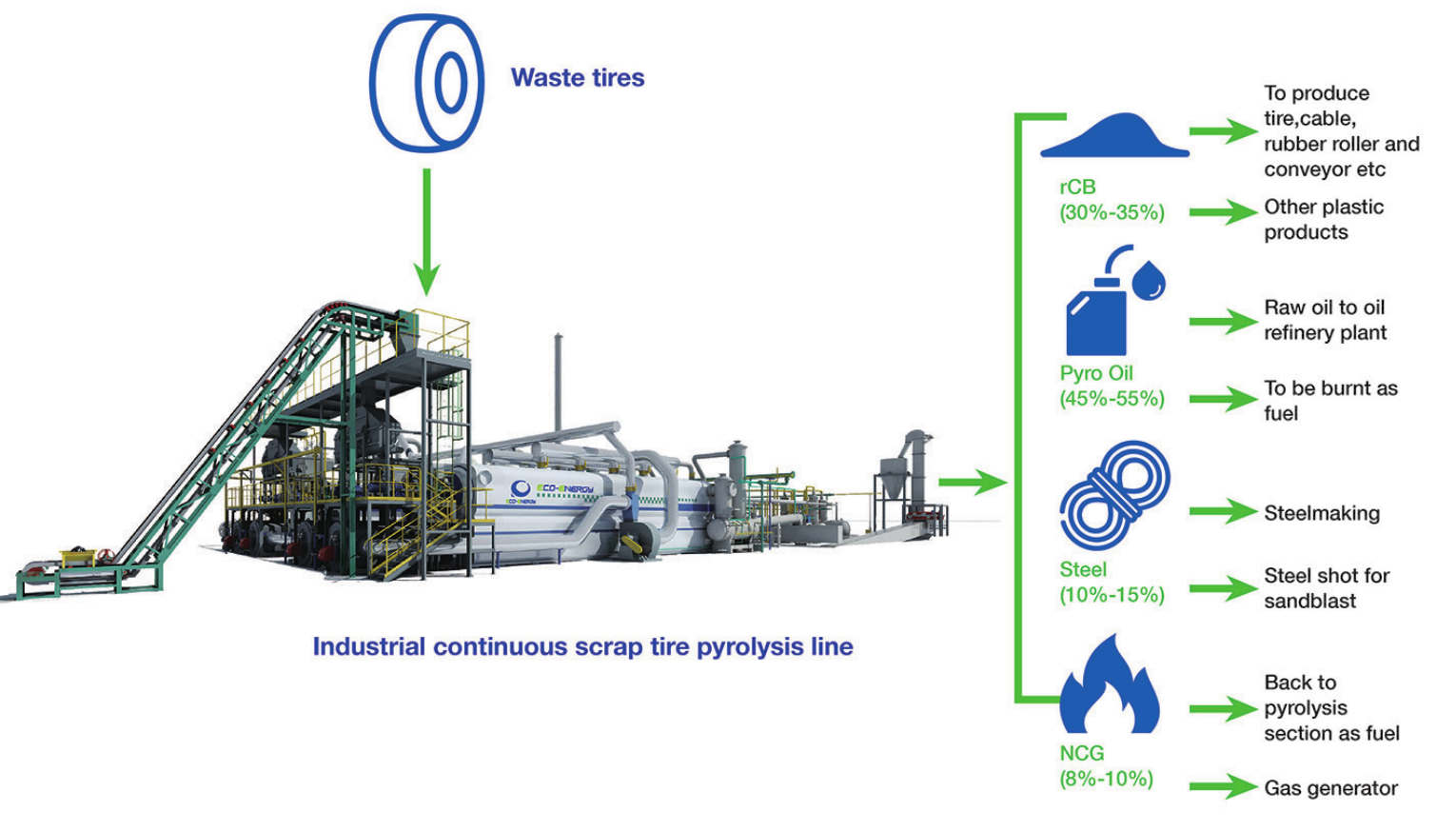

The pyrolysis of waste tires utilizes the thermal instability of its polymers. In the oxygen-free and oxygen-poor environment, it is heated back to a small molecule or monomer state to yield recycled oil (pyrolysis oil), carbon black, steel wire and other resource products.

The Application of Scrap Tire Pyrolysis Products

The Application of Scrap Tire Pyrolysis Products

Pyro oil can be used as fuel or raw oil in the petrochemical industry, and is an important basic chemical raw material. It can be used as a substitute for crude oil and has high economic value.

Carbon black is a basic chemical raw material, used as a reinforcing agent and filler for rubber, as well as a colorant for inks, paints and plastics, as well as an ultraviolet light shielding agent for plastic products, etc., with a wide range of uses.

The steel wire can be resmelted into high-quality steel, and can also be made into granules, which can be used as rust removal materials and sandblasting steel shots.

The non-condensable combustible gas is recycled to the furnace for reuse as fuel.

According to estimates, every 10,000 tons of waste tires pyrolyzed can produce 4,500 tons of pyrolysis oil, 800 tons of NCG, 3,500 tons of carbon black, and 1,200 tons of steel wire. The global annual output of waste tires exceeds 1 billion. At present, when the market demand for crude oil, carbon black, and steel wire is large and the price advantage is obvious, the potential huge commercial value is a huge blue ocean market.

Niutech-Specializing In Scrap Tire Pyrolysis Plant In More Than 30 Years

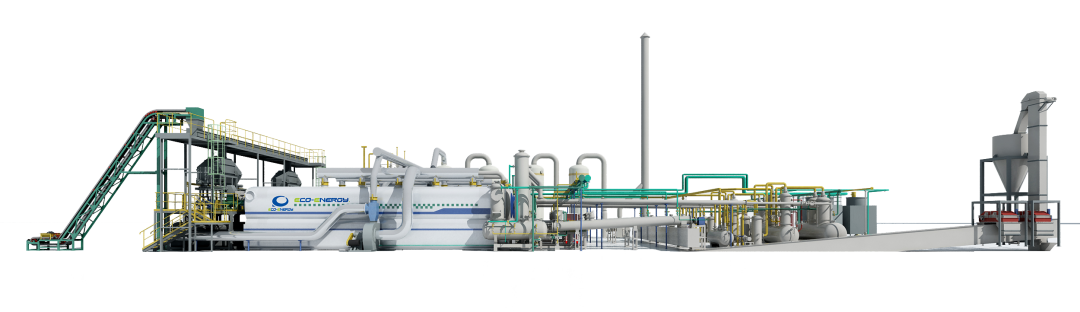

Niutech Environment Protection Corporation has focused and accumulated more than 30 years in the research and development of organic waste pyrolysis technology. The self-developed industrial continuous waste tire pyrolysis production line realizes the resourceful, harmless and reduced disposal of waste tires.

Waste tire pyrolysis technology and equipment have been applied to waste tire treatment bases in many countries on four continents, and industrialized in Germany, the United Kingdom, the United States, Hungary, Turkey, Estonia, India, Thailand, Malaysia, Iraq and other countries. The application has achieved high economic benefits while solving the pollution of waste tires, and has been highly praised by customers.

Waste tire pyrolysis technology and equipment have been applied to waste tire treatment bases in many countries on four continents, and industrialized in Germany, the United Kingdom, the United States, Hungary, Turkey, Estonia, India, Thailand, Malaysia, Iraq and other countries. The application has achieved high economic benefits while solving the pollution of waste tires, and has been highly praised by customers.

Email: contact@niutech.com

Tel: 86 531 86196301

No comment