“White pollution” is figurative term for people’s environmental pollution caused by plastic waste, which is usually refers to the pollution caused by various types of household plastic products made from polystyrene, polypropylene, polyvinyl chloride and other polymer compounds.tion” is figurative term for people’s environmental pollution caused by plastic waste, which is usually refers to the pollution caused by various types of household plastic products made from polystyrene, polypropylene, polyvinyl chloride and other polymer compounds.

The traditional waste plastics disposal methods such as landfilling and incineration not only waste a large amount of land, but also produce large amounts of carbon dioxide and other environmentally harmful toxic gases, contributing to the greenhouse effect and the formation of acid rain.

So far, countries around the world are advocating the “plastic reduction”. While controlling it from the source, it also need recycle and dispose of waste plastics in the existing environment.

Researches find many new methods to plastic waste recycling. The most universal method is to convert waste plastics into energy by pyrolysis technology.

So what kinds of plastics waste can be disposed of by waste plastic pyrolysis technology?

Pyrolysis technology is extremely inclusive of raw materials. It can handle single types of waste plastics, such as polyethylene, polypropylene, polystyrene, polytetrafluoroethylene, polyvinyl chloride, polyester, etc., as well as mixed plastics with complex compositions, and even low-value, contaminated plastics that are not easy sorted and can’t be eliminated by traditional physical recycling.

What products can be obtained after pyrolysis of waste plastics?

Ⅰ.To Produce Acrylic Wax

The waste plastics are first heated at an appropriate temperature to melt them into a low molecular fluid state, and then the low molecular fluid with impurities removed is further heated and cracked, and the cracked evaporates are fractionated to obtain a useful solid wax.

II.Extract gasoline and diesel from waste plastics

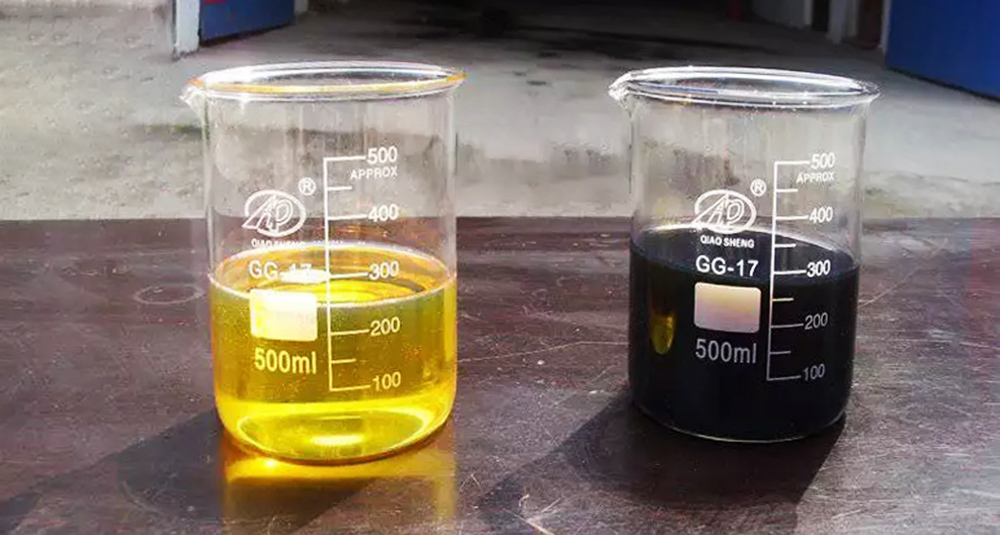

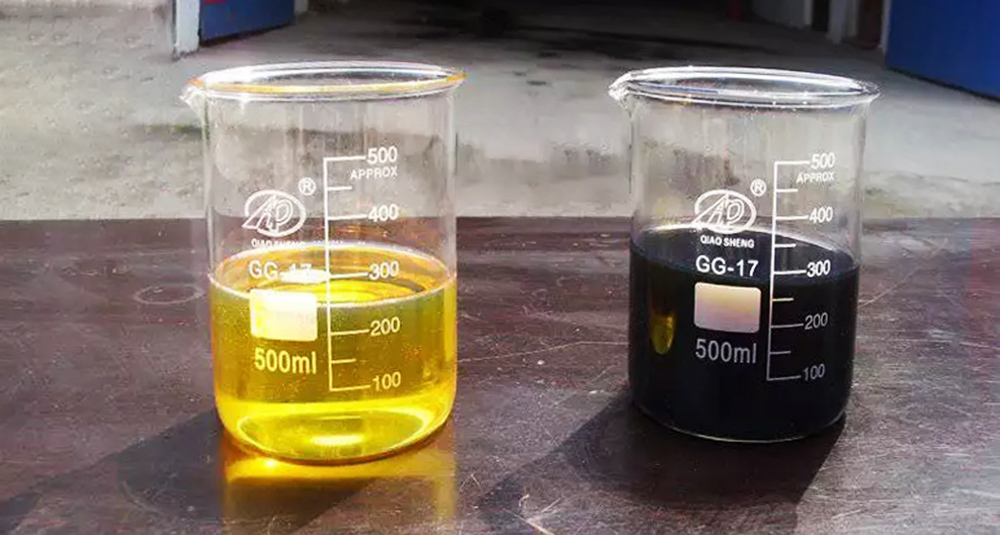

Turning waste plastics into gasoline and diesel is a better way to recyle plastic. After pyrolysis, customers can obtain pyrolysis oil, then

Waste plastics are pyrolyzed to obtain pyrolysis oil, which is refined to gasoline and diesel fractions. This way not only solves waste plastic pollution, but the outputs can replace crude oil and realize energy substitution.

As a pyrolysis equipment manufacturer in China, NIutech has independently developed mature pyrolysis equipment for waste plastics, which can realize the process and obtain high-quality oil, which can be applied in industrial production or as an alternative to traditional fuels.

Ⅲ.Obtain higher alpha olefins

Alpha olefins is an important chemical material, which can produce biodegradable and efficient surfactants as well as to synthesize α-olefin lubricants, plasticizers, ore flotation agents and so on.

After pyrolysis, waste plastics will release pyrolysis gas. And the pyrolysis gas is rapidly exported and then subjected to quenching, fractionation, and cooling to obtain liquid higher α-olefins.

The above three methods all use waste plastics as raw materials. Waste plastics come from a wide range of sources, with sufficient supply and low cost. The outputs of pyrolysis machine are widely used and have high economic value; they also completely solve most of the white pollution and have high social and environmental value, which is a green project that is conducive to the “global reduction of plastics”.

With the global emphasis on plastic pollution, waste plastic pyrolysis technology and equipment have been promoted in many countries and regions around the world. Niutech’s waste plastic pyrolysis technology and equipment have been widely used in China, the United States, Denmark, the United Kingdom, South Korea, Thailand and other countries and have achieved good economic and environmental benefits.

Web: www.bestpyrolysis.com

Tel: 86 531 86196301

Email: contact@niutech.com

No comment